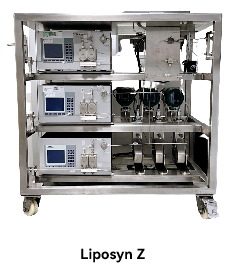

ENO Bio has developed proprietary key equipment for mRNA-LNP formulation, resulting in multiple patent families covering structural design, hydrodynamic characteristics, and manufacturing processes. Based on the impinging jet principle, ENO Bio's lipid nanoparticle synthesizer enables highly efficient encapsulation of active pharmaceutical ingredients with lipids.

This LNP production equipment achieves a stable output of 50,000 doses per hour. A single unit can meet medium-scale mRNA vaccine production demands, while multiple units operating in parallel can support large-scale vaccine production. In practical operation, the equipment runs stably, with a quality fluctuation coefficient of less than 5% during 8 hours of continuous operation. LNPs produced under identical conditions exhibit highly consistent quality attributes across batches, including key metrics such as particle size, size distribution, encapsulation efficiency, and stability. All materials used in the equipment are sourced domestically, reducing production costs and mitigating risks associated with the uncertainty of foreign component supply, thereby ensuring a stable and autonomous production supply chain.

In addition to the impinging jet LNP production equipment for pilot and commercial-scale manufacturing, ENO Bio has also developed the Liposyn X, an all-in-one intelligent LNP synthesizer that operates via a touchscreen without requiring an external computer. It features two independent liquid delivery channels, handles sample volumes from 0.4 to 15 mL, and offers a flow rate accuracy of ≤ ±2%. Equipped with various syringe adapters and standard LNP synthesis chips, it can produce LNP particles ranging from 40 to 200 nm. This system is primarily used for small-scale process development, enabling precise control of flow rates and ratios. It is suitable for LNP formulation screening, supporting high-throughput and rapid screening applications.

Furthermore, the Liposyn Y lipid nanoparticle synthesizer features two positive pressure output channels with a pressure range of 0 - 8000 mbar. It processes sample volumes from 1 to 100 mL with a flow rate accuracy of ≤ ±2%. Equipped with various adapters and standard LNP synthesis chips, it produces LNP particles in the 60-300 nm range. Its chips are made of PDMS material and comply with cGMP standards, making the system suitable for small-scale process development.